Machining Process:

Machining processes involve material removal to form a desired shape, and the steps typically include analyzing the design, selecting machining techniques and tools, programming the machine, and finally, executing the machining operations.

Here’s a more detailed breakdown of the machining process steps:

1. Analysis and Approval of Technical Drawings:

The process begins with a thorough analysis of the technical drawings of the workpiece to understand its geometry, dimensions, and required tolerances. This step ensures that all the necessary information is available for the subsequent stages of the machining process.

2. Modeling or Prototyping:

After analyzing the technical drawings, a model or prototype of the part may be created to visualize the final product and identify potential issues early on.

This step can help in refining the design and ensuring that the final product meets the required specifications.

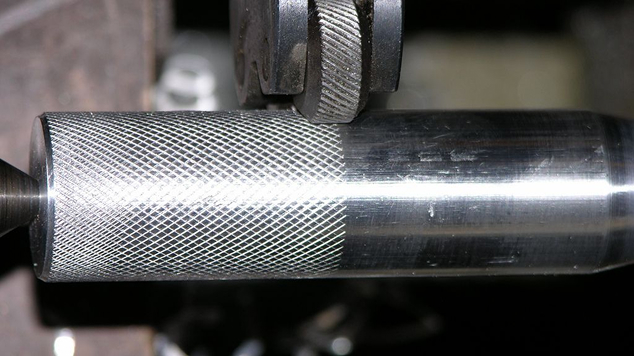

3. Selecting Machining Techniques:

The next step involves selecting the appropriate machining techniques based on the material, shape, and required tolerances of the workpiece. Common machining techniques include turning, drilling, milling, grinding, sawing, reaming, knurling, shaping, and face milling. The choice of technique will depend on the type of material, the desired surface finish, and the complexity of the part.

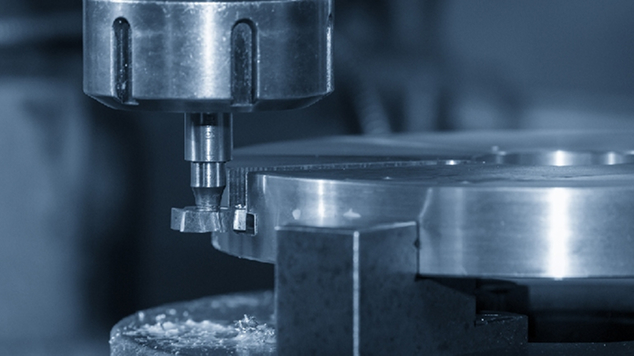

4. Choosing the Right Machine Tool:

Once the machining techniques are selected, the appropriate machine tools need to be chosen. This includes selecting the right lathe, milling machine, drill press, grinder, or other specialized equipment. The choice of machine tool will depend on the size, shape, and material of the workpiece, as well as the required accuracy and precision

5. Process Planning and Programming:

Process planning involves creating a detailed sequence of machining operations to transform the raw material into the final product.This includes determining the order of operations, the cutting parameters (speed, feed rate, depth of cut), and the required tooling.The process plan is then translated into a machine-readable program, which is used to control the machine tool during the machining process.

6. Executing the Machining Operations:

The final step involves executing the machining operations according to the process plan and program.This includes loading the workpiece into the machine tool, setting up the cutting tools, and initiating the machining process.Throughout the process, it is important to monitor the machine tool and the workpiece to ensure that the desired results are achieved.

7. Post-Machining Operations:

After the machining operations are completed, the workpiece may require further processing, such as deburring, cleaning, or surface finishing.These operations are necessary to ensure that the final product meets the required specifications.