Destructive & Non-Destructive Testing Process:

Destructive testing alters or damages the material being tested to gather information, while non-destructive testing (NDT) examines materials without causing harm, allowing for continued use.

Here’s a more detailed explanation:

Destructive Testing:

- Tensile Testing:

Measures the force required to break a material under tension, providing information about tensile strength, yield strength, and ductility. - Compressive Testing:

Measures the force required to crush a material under compression, providing information about compressive strength. - Bending Testing:

Measures the force required to bend a material until it fractures, providing information about ductility and bending strength. - Hardness Testing:

Measures a material’s resistance to indentation or scratching, providing insights into its wear resistance and machinability. - Fatigue Testing:

Measures a material’s ability to withstand repeated loading and unloading cycles, providing information about its fatigue life. - Impact Testing:

Measures a material’s ability to absorb energy under sudden impact, providing information about its toughness. - Residual Stress Testing:

Measures the stresses that remain in a material even after it has been deformed or processed, which can affect its overall performance. - Bend Test:

Bends a straight plate specimen through 180° around a former to check for cracks.

Non-Destructive Testing (NDT):

- Purpose:

To inspect materials and identify defects or flaws without altering or damaging them.

Examples:

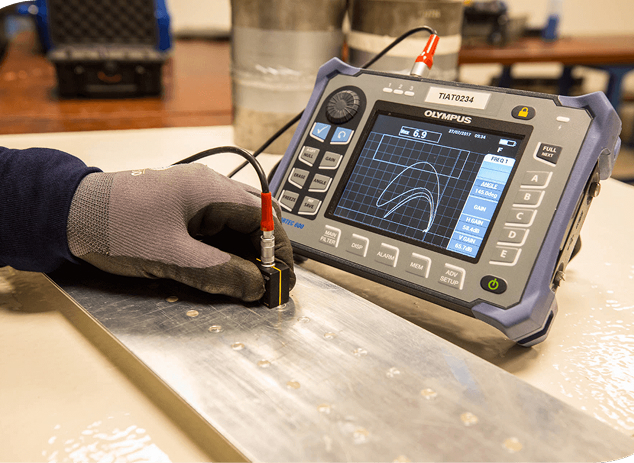

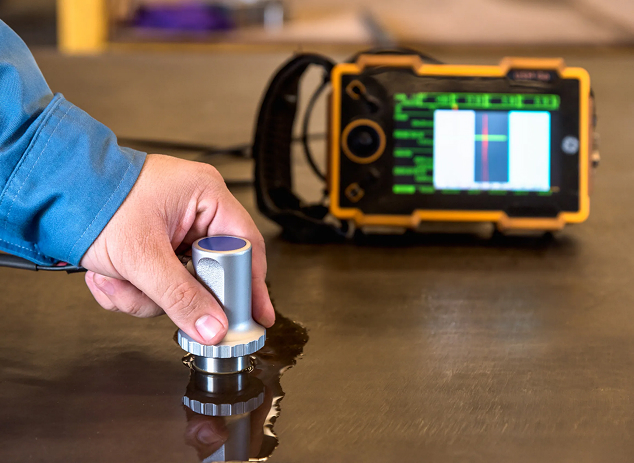

- Ultrasonic Testing (UT):

Uses high-frequency sound waves to detect internal flaws and assess material thickness. - Radiographic Testing (RT):

Uses X-rays to reveal internal defects, similar to medical X-rays. - Magnetic Particle Testing (MT):

Detects surface and near-surface flaws in ferromagnetic materials by using magnetic fields and particles. - Liquid Penetrant Testing (PT):

Uses a dye to reveal surface cracks or pores by capillary action. - Eddy Current Testing (ET):

Uses electromagnetic induction to detect flaws in conductive materials. - Visual Testing (VT):

Involves visual inspection for surface defects.